ddrueding

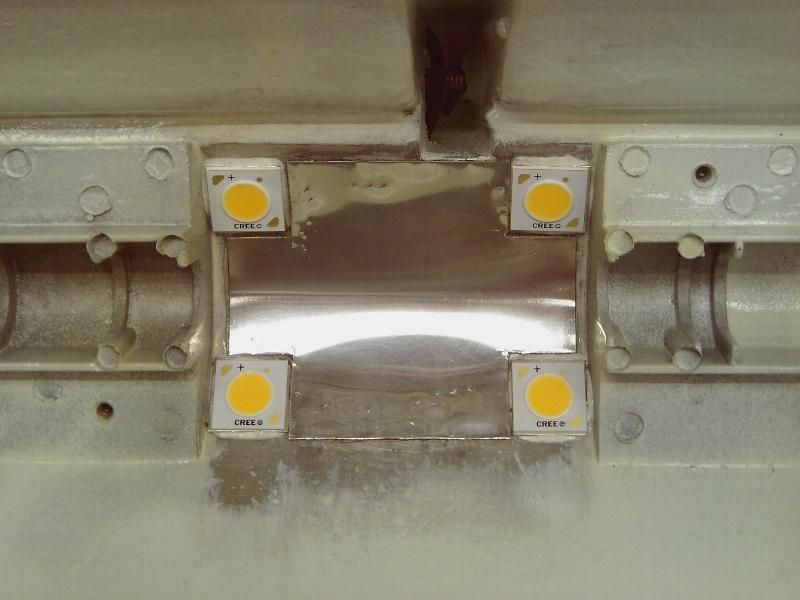

Fixture

I'm imagining this to mostly be a dialogue between JTR and I, but all input is welcome. It will probably conclude with me having JTR build something for me as he has in the past (happy customer).

The outdoor wall lights are already installed and are 5000k (Lumark Crosstour), I'd like the ground lights to match. The goal is to make "up-lights", where the fixture is underground and light is emitted upwards through an opening at the surface.

At the moment I'm planning on the body of the fixtures to be made from copper/brass plumbing parts:

(from bottom to top) cap, male/male coupler, flange, gasket, glass. Somewhere in there I'd need to sneak in the wire. Probably put some desiccant at the bottom to discourage fogging. I know plumbing is good at being waterproof, and I was thinking that brass fittings would also be good at dissipating the heat of the unit. I'm in the process of drawing this up in SolidWorks to clarify the idea.

Now for the challenging bits:

1. I want to be able to control a chain of these lights together.

2. I want the chain to be quite long (15' with 5 units primarily, but another that is 50'+ and 15 units would be awesome)

3. The wire itself is going to be laid under some bark (not even buried), so low-voltage is a must.

4. The control unit should support being dimmed from a standard wall dimmer.

And the easy bits:

1. I can give exact wire lengths so calculations and connections can be made in advance.

2. Brightness does not need to be high.

Thoughts? Thanks!

The outdoor wall lights are already installed and are 5000k (Lumark Crosstour), I'd like the ground lights to match. The goal is to make "up-lights", where the fixture is underground and light is emitted upwards through an opening at the surface.

At the moment I'm planning on the body of the fixtures to be made from copper/brass plumbing parts:

(from bottom to top) cap, male/male coupler, flange, gasket, glass. Somewhere in there I'd need to sneak in the wire. Probably put some desiccant at the bottom to discourage fogging. I know plumbing is good at being waterproof, and I was thinking that brass fittings would also be good at dissipating the heat of the unit. I'm in the process of drawing this up in SolidWorks to clarify the idea.

Now for the challenging bits:

1. I want to be able to control a chain of these lights together.

2. I want the chain to be quite long (15' with 5 units primarily, but another that is 50'+ and 15 units would be awesome)

3. The wire itself is going to be laid under some bark (not even buried), so low-voltage is a must.

4. The control unit should support being dimmed from a standard wall dimmer.

And the easy bits:

1. I can give exact wire lengths so calculations and connections can be made in advance.

2. Brightness does not need to be high.

Thoughts? Thanks!